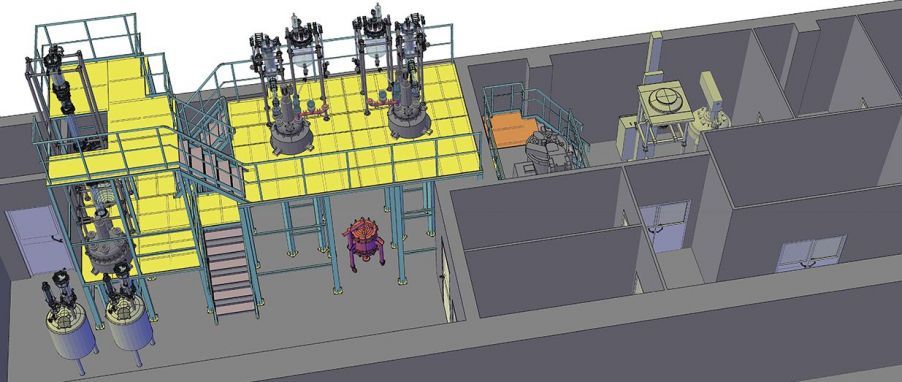

DESIGN OF A PRODUCTION SITE FOR SYNTHESIS AND PURIFICATION OF CHEMICAL SUBSTANCES

Objective: to develop working documentation for the site of synthesis and purification of a chemical substance with the site of regeneration of used solvents.

To solve the task set by the customer, REATORG has designed a site that allows for the synthesis, recrystallization, filtration, drying, dispersion and packing of various chemical substances.

As part of the site, universal reactor systems based on glass enameled reactors, enameled filters and fluoroplastic coated filters have been developed. Systems have a high level of automation, ensure safe conduct of processes in an explosive room, compact and ergonomic.

The solvent recovery section with operating in automatic mode distillation column was also worked out.

The project uses customized technical solutions:

• stainless filter bag with a heating jacket with an internal PFA coating and a fluoroplastic fabric, significantly reducing the cost of the filtration area - instead of an enameled Druk filter;

• explosion-proof automatic rectification system for solvent recovery;

• liquid dosing system with a pneumatic diaphragm pump, which allows setting the total volume and dosing rate, in an explosion-proof version;

• thermostats that use steam as a source of heat and refrigerated water as a source of cold.