RECTIFICATION COLUMNS OF REATORG TECHNOLOGIES WITHIN THE PROGRAM OF IMPORT SUBSTITUTION OF HIGHLY PURE CHEMICAL PRODUCTS

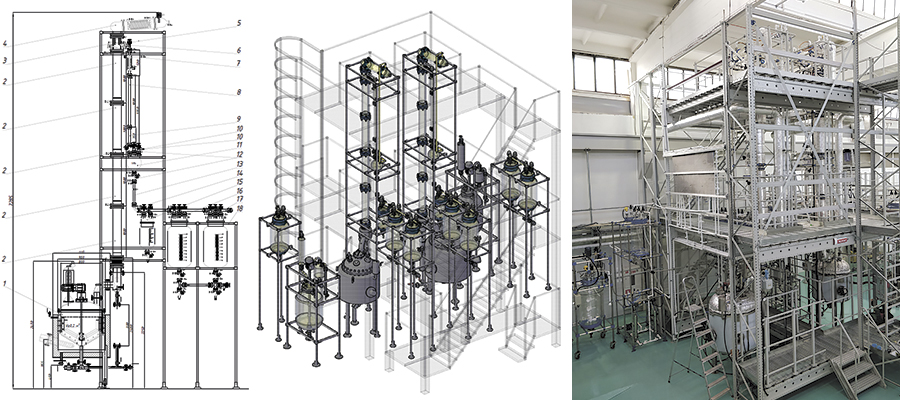

REATORG completed the design, manufacture, installation and commissioning of two modules to produce highly pure substances as part of the import substitution program for highly pure chemical products.

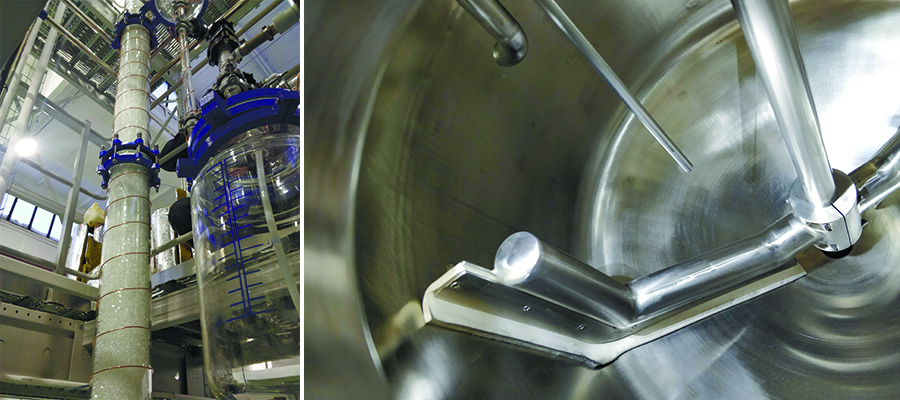

To solve the task set by the customer, REATORG developed two modules for producing highly pure substances, each of which consisted of a glass reactor (200 and 50 l), a filtration module, and a distillation unit, which in turn consisted of AISI 321 stainless steel distillation cube, four-meter columns, receivers, measuring devices and piping made of borosilicate glass grade 3.3.

The complexity of the task was that the customer with a limited budget needed to get a turnkey solution.

REATORG specialists found technical solutions, prepared 3D-models of plants and design drawings. An automation system has been developed and installed. Steel components, system assembly and commissioning were also performed.