DESIGN OF API PRODUCTION (34 000 KG / YEAR)

REATORG performed pre-design preparation, developed a conceptual design and design documentation for JSC “BIOKHIMIK”.

The team of REATORG specialists was assigned the task of conducting pre-project preparation, developing a conceptual design, and preparing project documentation (section "Technological solutions") for the organization of the production of API.

In the process of pre-design preparation, the list of the customer's products, production volumes, description of the synthesis and purification processes were analyzed.

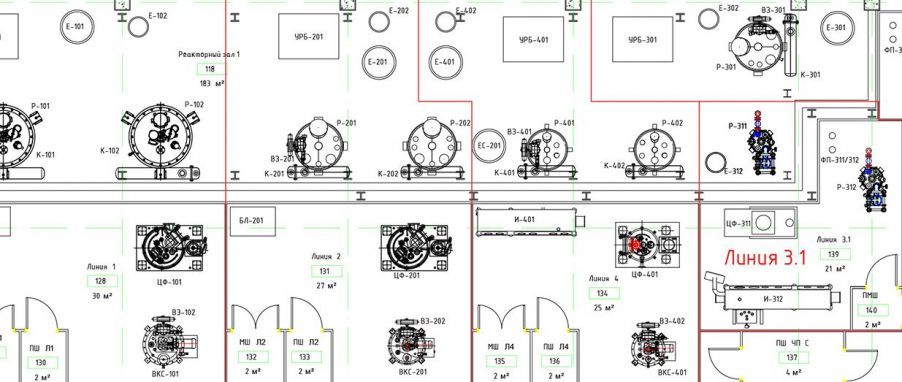

The design process began with the drawing up of technological schemes and specifications of the main technological equipment. Having completed the hardware design of the process, we moved on to one of the most difficult tasks - the placement of a new production facility in an existing building. Many layouts were proposed, adjustments were made to production volumes, additional axes were added to the building, but the best option was eventually found.

After agreeing on the final layout, the project documentation development process was started. REATORG specialists have developed 3 volumes of the Technical specifications section:

1. Technological solutions

2. Technological solutions. Clean environments

3. Technological solutions. Supply of compressed air and process gases.

The Technical Specifications section was developed in accordance with the Decree of the Government of the Russian Federation No. 87 "On the composition of sections of project documentation and requirements for their content", but was not limited to it.

In particular, within the framework of the first volume, technical tasks were prepared for the development of related sections, including the task for the design of a separate storage warehouse for flammable liquids and local treatment facilities. A system of heating and cooling of the capacitive equipment was also developed using secondary thermostats that mix heat flows from two lines – high-temperature (thermal oil) and low-temperature (polymethylsiloxane): the thermal oil is heated using technical steam, and the polymethylsiloxane is cooled in a low-temperature chiller. A nitrogen inertia system was developed to prevent the formation of explosive mixtures in-tank equipment and filter centrifuges.

Within the framework of the second volume, a system for obtaining, storing and distributing highly purified water, installations for preparing, heating and supplying cleaning solutions, and a system for decontamination of technological equipment for the production of API of category 1.2B of microbiological purity using hydrogen peroxide vapors were developed.

Within the framework of the third volume, compressor equipment was selected, a compressed air distribution system was designed, nitrogen generators, filters for cleaning were selected, and a distribution system was designed. A vacuum system was designed, vacuum pumps were selected, and the area of heat exchangers for condensing solvent vapors entering the system during drying processes was calculated.

At the moment, the implementation of the project has begun. REATORG acts as a supplier of process equipment, a contractor for the installation of equipment and process pipelines, and commissioning.