DEVELOPMENT OF WORKING DOCUMENTATION FOR THE ORGANIZATION OF THE SYNTHESIS AND PURIFICATION SITE OF HIGHLY ACTIVE API

Customer: SEVER PHARMACEUTICALS LLC

Objective: development of working documentation for the sections "Technological solutions" and "Automation of technological solutions" in order to carry out a major overhaul of the Izvarino Pharma building.

At the end of 2022, a team of specialists from REATORG LLC was tasked with analyzing the conceptual design and initial data, developing planning solutions for the new tasks of the Customer, and preparing working documentation for organizing the production of API.

The second task of REATORG LLC was to locate a laboratory area in a separate dedicated area, allowing the Customer to analyze the quality of products and research in the development of new substances.

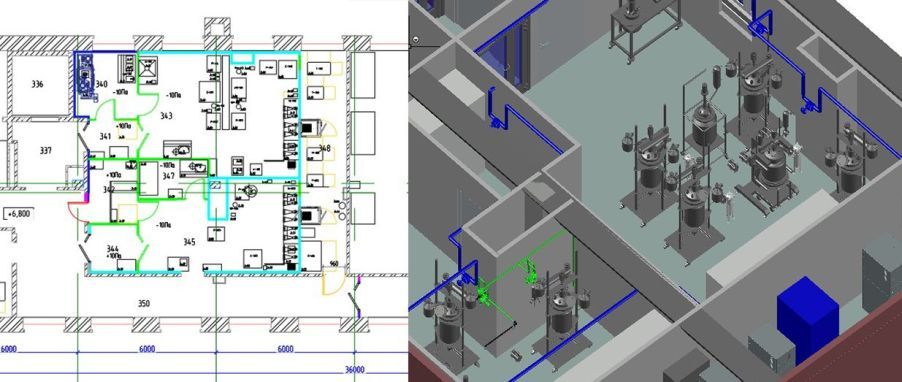

In the process of analyzing the structure of the 1966 building, decisions were made that allowed the Customer to use the existing premises with minimal adjustments in order to accommodate the synthesis and recrystallization of the API and the laboratory area.

The design process began with the preparation of flow diagrams and specifications for the main process equipment. Solutions have been developed and the range of equipment has been selected to meet the requirements in terms of isolation of the process from the environment, risks of decontamination and threats to personnel, while allowing the equipment to be used with maximum energy efficiency.

Having completed the hardware design of the process, we moved on to one of the most difficult tasks - locating a new production facility in an existing building. A lot of layout layouts were proposed, categories of premises for fire and explosion hazard were determined, decisions were made to allocate premises for auxiliary technological equipment.

As a result, we placed production in accordance with all the requirements and rules in force at large production sites.

After agreeing on the final layout, the process of preparing working documentation began. REATORG LLC specialists developed the volumes of the “Technological solutions” section:

1. Technological solutions. Technology of synthesis and recrystallization.

2. Technological solutions. Laboratory block.

3. Technological solutions. Automation of the technological process.

All documentation has been developed in accordance with the requirements of GOST R 21.101-2020. Basic requirements for design and working documentation”, “Decision of the Council of the Eurasian Economic Commission No. 77 “On approval of the Rules of Good Manufacturing Practice of the Eurasian Economic Union” dated November 3, 2016”, “GOST R ISO 14644-1-2017. Cleanrooms and related controlled environments. Part 1. Classification of air purity. ISO 14644-1-99”, “GOST R ISO 14644-4-2002. Cleanrooms and related controlled environments. Part 4: Design, construction and commissioning”, but is not limited to.

Terms of reference for the development of related sections were prepared, requirements were worked out to ensure the protection of personnel and the environment from the consequences of emergency situations and accidents.